|

Item |

Specifications |

|

Model Series |

ML-BIB1300 |

|

Max. Production Speed |

76 pcs/min (in 4-lane mode) |

|

Max. Web Feeding Speed |

Max. Web Feeding Speed |

|

Bag Capacity Range |

1L-220L |

|

Film Materials |

All heat-sealable materials, including pure PE |

|

Film Width |

Max. 1300 mm |

|

Positioning Accuracy |

±0.2mm |

|

Sealing Strength |

20N/15mm (for pure PE) |

|

Valve Type |

All 1-inch valves |

|

Control System |

Panasonic (Servo Motors) |

|

Power Supply |

3-Phase380V/50Hz |

|

Production Mode |

1-lane, 2-lane, or 4-lane output |

|

Rated Power |

98 kW |

|

Air Pressure |

0.6 MPa |

|

Energy Consumption |

10 kWh |

|

Weight / Dimensions |

Approx.17 Tons / 26000×4590×2380mm |

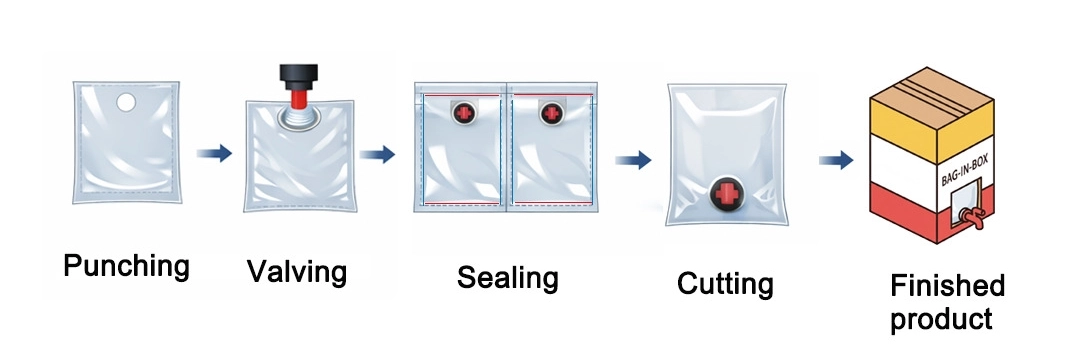

Our BIB bag making machine is engineered for precision and efficiency, delivering up to 18 bags per minute with a maximum bag width of 1300mm and length of 800mm (double format). Designed to handle all heat sealing materials, including pure PE, this high-performance heat sealing bag production line supports a film width of 1350mm and accommodates roll diameters up to 800mm. Its robust construction spans 20000mm x 4890mm x 2380mm and weighs 9 tons, ensuring industrial-grade stability and durability. Whether you're packaging liquids, semi-liquids, or paste-based products, this 24/7 continuous operation bag production line provides reliable, high-speed output with consistently strong sealing performance.

It is perfectly suited for producing packaging such as Tomato Sauce Bag-in-Box, Coffee Beans Bag-in-Box, Oil Bag-in-Box, and Milk Bag-in-Box.

Firstly, it adopts high-precision ultrasonic device, which can accurately calculate the diameter of the roll. And, with the position calculation of the absolute value encoder of the floating roll, it ensures the consistent pressure of each roll of film. Secondly, the bag-making speed is adjustable, which can be flexibly changed according to the production demand to improve the operation performance. In addition, it is equipped with automatic film breakage detection and alarm function. Once film breakage is detected, an alarm can be issued in time to avoid production interruption. ML-1300BIB is suitable for producing BIB bag-in-box made of plastic film, composite material, and other single materials.

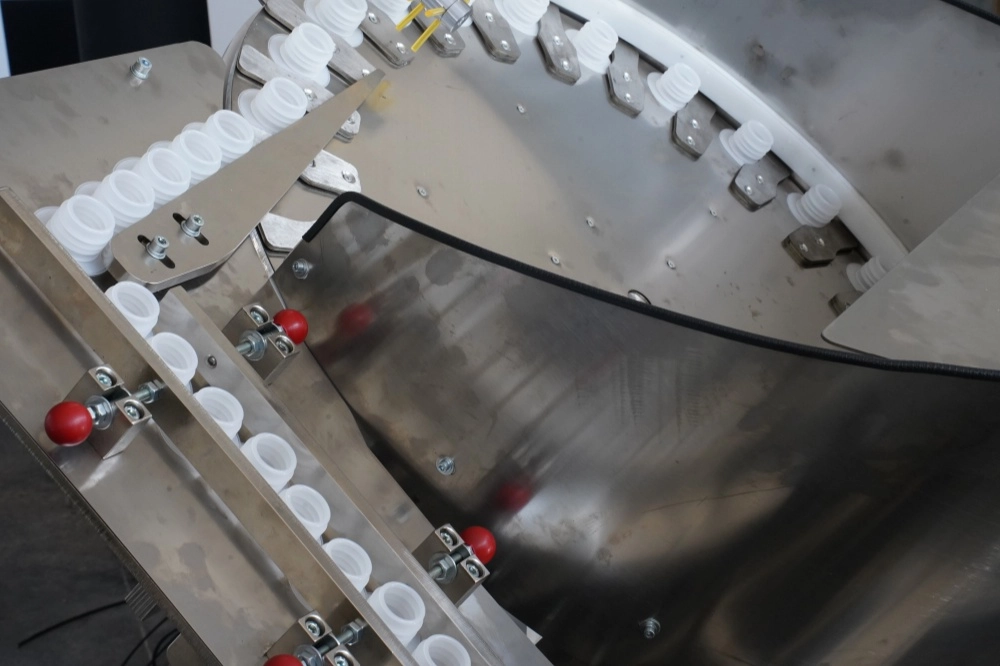

Q1: What types of valves can the ML-1300 BIB bag making machine handle?

A1: The machine is compatible with all standard 1-inch BIB (Bag-in-Box) valves via direct fitment.

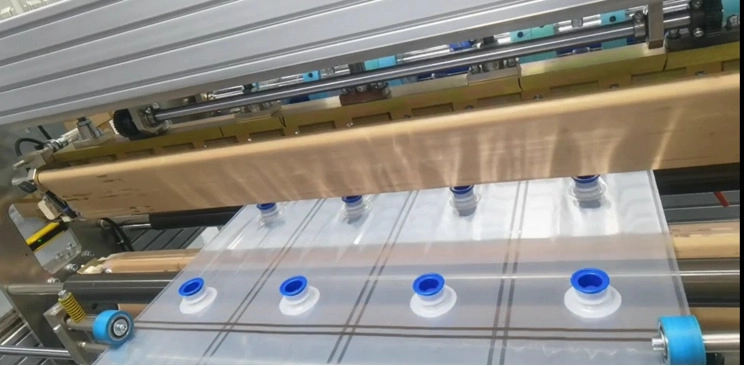

Q2: How does the ML-1300 BIB ensure valve sealing and leak prevention?

A2: We utilize CCD-controlled alignment with a precision of ±0.05mm. Combined with robotic valve mounting, we achieve 100% directional accuracy to ensure zero-leakage performance.

Q3: Does this machine require a long preheating period?

A3: No. Equipped with UPT Impulse Sealing Technology (instant heat and instant cool), production can begin immediately upon power-up. This eliminates the 20–30 minute warm-up time required by traditional machines.

Q4: Is the ML-1300 BIB noisy during operation?

A4: Thanks to our proprietary Silent Screening Technology, noise levels are kept below 60 dB, providing a "library-grade" quiet working environment.

Q5: How difficult is it to switch between different bag types?

A5: The process is highly efficient. Featuring a fully automated changeover system, preset parameters can be retrieved via a "One-Touch" interface. Transitioning from Bag A to Bag B takes only 3 minutes.

Q6: How many bags can the ML-1300 BIB produce at once?

A6: It features a multi-lane synchronous output system, capable of 2 Lane or 4 Lane production cycles.