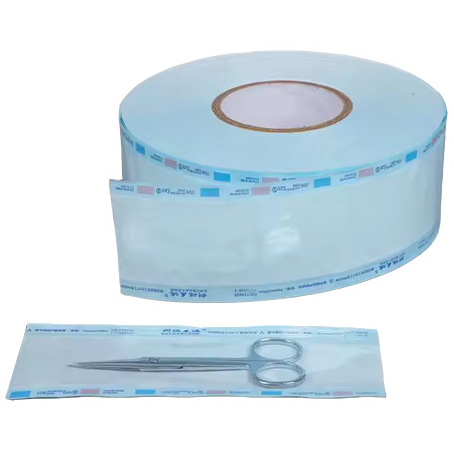

Paper-poly pouches are medical-grade packaging bags made from a combination of medical paper and transparent polyethylene (PE) film. This hybrid structure creates a sterile, durable, and easy-to-use pouch used widely in hospitals for packaging surgical instruments, medical devices, cotton products, syringes, catheters, and other daily consumables.

The paper layer allows sterilizing agents—such as steam, EO, or plasma—to pass through efficiently, while the poly layer provides a clear view of the contents and a strong barrier against contamination. Because of this dual functionality, paper-poly pouches have become one of the most trusted materials in hospitals for safe and sterile packaging.

Hospitals choose paper-poly pouches because they perfectly combine safety, convenience, and cost efficiency. The material structure and practical design address the common needs of medical staff and ensure reliable performance during daily operations.

Paper-poly pouches are designed to keep contaminants out.

The PE film offers a stable barrier against dust, moisture, and bacteria, while the medical paper layer reinforces the pouch’s strength and breathability. Together, they help maintain sterility until the moment of use. The heat-sealed edges also prevent accidental opening, making the pouches ideal for sharp or delicate tools.

One of the biggest advantages is sterilization versatility.

The medical-grade paper allows sterilizing agents to penetrate the pouch easily, ensuring instruments are fully sterilized. Hospitals commonly rely on paper-poly pouches because they work with:

Their compatibility reduces the need for multiple types of packaging, simplifying hospital workflows and lowering procurement cost.

The transparent poly side lets medical staff immediately identify the packaged items without opening the pouch, reducing errors and improving workflow efficiency.

Meanwhile, the paper side allows easy labeling, date marking, and barcoding. This is especially useful for tracking sterilization cycles and ensuring proper usage rotation.

Paper-poly pouches are designed for controlled peeling.

The peelable seal ensures that medical staff can open the pouch smoothly without particles or fibers contaminating the sterile items. Nurses and surgeons prefer this because it reduces the risk of accidental contamination and improves handling efficiency during surgeries or emergency procedures.

While not fully biodegradable, paper-poly pouches use far less plastic than traditional all-plastic medical pouches. The reduced plastic content makes them a lighter environmental choice and aligns better with hospital sustainability goals. Many healthcare facilities now actively prefer packaging that offers environmental benefits without compromising safety—making paper-poly pouches a popular option.

The performance of a paper-poly pouch depends heavily on how it is manufactured. Hospitals pay close attention to:

High-quality pouches prevent sterilization failures, reduce breakage during handling, and ensure long-term sterility. Consistency across batches is crucial because hospitals rely on predictable performance during large-scale daily usage. This is why many suppliers invest in advanced manufacturing technology to meet strict medical packaging standards.

The reliability of these pouches starts with the machine that produces them. Medical Paper-Poly Pouch Making Machines are specifically designed for healthcare packaging and plays a major role in ensuring pouch safety and consistency.

These machines offer several key advantages:

Ensures strong, uniform seals that withstand sterilization stress without breaking.

Keeps the paper and poly layers perfectly matched to prevent weak spots.

Produces pouches with consistent dimensions, which is essential for automated hospital sterilization workflows.

Ensures hygienic processing and avoids damage to delicate medical papers or films.

Allows manufacturers to keep costs competitive while maintaining strict quality requirements.

With advanced automation and intelligent controls, modern medical pouch making machines help manufacturers deliver stable, reliable, and safe paper-poly pouches that hospitals trust every day.

ML-600 Medical Paper-poly Pouch Making Machine

Paper-poly pouches have become a standard choice for hospitals because they combine strong protection, excellent sterilization compatibility, and user-friendly handling. Their transparency and labeling flexibility improve workflow efficiency, while their reduced plastic content offers environmental advantages.

However, the true reliability of these pouches begins with the right manufacturing technology. Medical Paper-Poly Pouch Making Machines ensure consistent quality through precise sealing, accurate sizing, and hygienic processing. As hospitals continue to demand safe and dependable packaging, high-quality production equipment will remain essential to supplying trustworthy paper-poly pouches for medical use.